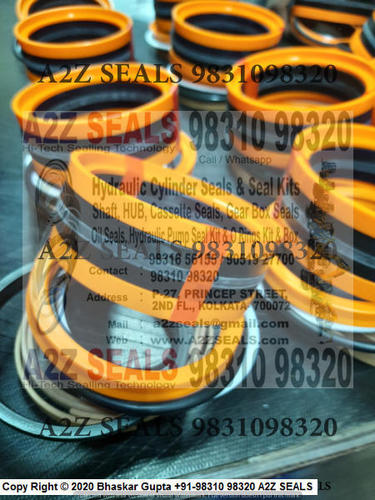

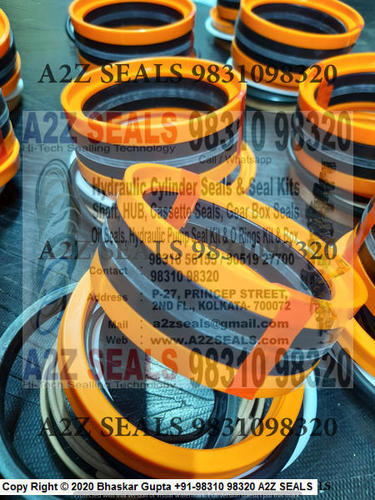

Floating Seals

Price 100.00 INR/ Set

MOQ : 1 Set

Floating Seals Specification

- Usage & Applications

- Used in construction machinery, mining equipment, excavators, tractors

- Capacity

- Heavy-duty

- Features

- Abrasion resistance, Long service life, Oil & dust sealing

- Size

- Multiple Sizes Available (Standard and Custom)

- Surface Finish

- Smooth

- Noise Level

- Low

- Diameter

- Range: 50 mm to 400 mm

- Shape

- Round

- Lubricating System

- Self-lubricating

- Drive Type

- Mechanical

- Product Type

- Floating Seals

- Material

- High-grade Alloy Steel

- Technology

- Precision Casting

- Pressure

- Suitable for High Pressure Applications

- Surface Treatment

- Black Oxide Finish

- Dimension (L*W*H)

- Customizable as per requirement

- Weight

- Varies as per size

- Color

- Black

- Rust Resistance

- Excellent

- Installation

- Easy press-fit type

- Hardness

- HRC 60~68

- Packing Type

- Wooden Box/Carton

- Operating Temperature

- -40°C to +120°C

- Flexibility

- High Elasticity

- Compatibility

- Suitable for OEM replacement

- Seal Type

- Mechanical Face Seal

- Waterproof Grade

- IP68

Floating Seals Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 100 Sets Per Day

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About Floating Seals

The floating seal is a simple product made up of two components: a seal ring made of special cast iron and a rubber component (O-ring / gasket). Two identical seals form a pair when used. The sliding component, the seal ring, is supported by the rubber component, so it does not come in contact with the shaft, closely conforming to the radial and thrust motion of the shaft. Floating Seals developed for slurry applications, the seal ring is very hard, wear resistant and made of corrosion resistant material. The rubber component presses the sliding surface of the seal ring and also acts as a seal. It is therefore made of a material that has a cold temperature and very high durability to heat and has a compressive strength that is long enough to extend its compression life.Engineered for Tough Conditions

Designed to withstand extreme temperatures and heavy pressures, our Floating Seals offer reliable sealing for construction and mining machinery. Their high elasticity and mechanical drive type ensure optimal performance in harsh, abrasive environments, reducing downtime and maintenance costs. The robust alloy steel construction, reinforced by black oxide surface treatment, guarantees resistance to rust and corrosion, making them an ideal long-term solution for OEM replacements.

Flexible Installation & Custom Sizing

Installation of these seals is straightforward thanks to an easy press-fit design. With a diameter range of 50 mm to 400 mm and options for standard or custom sizes, they adapt seamlessly to various equipment specifications. Customized dimensions and flexible weight options make them suitable for a wide array of machines, while secure packing in wooden boxes or cartons ensures safe delivery.

Advanced Sealing Technology for Heavy Duty Use

Utilizing advanced self-lubricating technology and precision casting, our seals maintain smooth, low-noise operation under the toughest workloads. Their IP68-rated waterproof properties, high abrasion resistance, and oil and dust sealing capabilities highlight their suitability for long-term, heavy-duty applications in both OEM and aftermarket machinery.

FAQs of Floating Seals:

Q: How do I install the floating mechanical face seal in my equipment?

A: Installation is simple due to the press-fit design. Ensure the mounting area is clean and dry, then carefully press the seal into position using appropriate tools. Follow the manufacturers guidelines to achieve optimal sealing and avoid unnecessary pressure that could damage the seal.Q: What applications are best suited for these floating seals?

A: These seals excel in heavy-duty equipment such as construction machinery, mining tools, excavators, and tractors. Their oil and dust sealing, along with high elasticity and abrasion resistance, make them ideal for harsh, high-pressure environments typically found in these industries.Q: When should I consider replacing a mechanical face floating seal?

A: Replacement is recommended when you observe signs of leakage, excessive noise, or when routine maintenance identifies wear. Adhering to manufacturer service intervals ensures continuous protection and maximizes your equipments operational lifespan.Q: Where can I use these seals regarding temperature and pressure conditions?

A: Our seals are built to operate in temperatures between -40C and +120C and are suitable for high-pressure applications. This makes them versatile for use across various environments, from cold storage facilities to hot, high-load industrial sites.Q: What benefits does the self-lubricating system provide?

A: The integrated self-lubrication minimizes friction and wear, resulting in longer service intervals and reduced noise. This feature enhances seal longevity and reliability, even in challenging operational conditions.Q: How does the IP68 waterproof rating enhance usage?

A: The IP68 rating ensures the seal is completely dustproof and can withstand continuous submersion in water. This offers superior protection against environmental contaminants, making it reliable for outdoor and demanding on-site applications.Q: What makes these seals suitable for OEM replacement?

A: Engineered to exacting standards with customizable sizing, high tolerance, and premium materials, these seals match or exceed OEM quality. Their ease of installation and compatibility with multiple machinery models ensure they are a reliable choice for new builds and replacements.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Spare Parts Category

Kaplan Seals

Price 100.00 INR / Set

Minimum Order Quantity : 1 Set

Shape : Ring/round

Lubricating System : Integrated or external lubrication as per system

Power Source : Hydraulic

Noise Level : Low noise operation

Hydraulic Jack Seal

Price 100.00 INR / Set

Minimum Order Quantity : 1 Set

Shape : Round

Lubricating System : Selflubricating material

Power Source : Hydraulic

Noise Level : Silent operation

hydraulic piston seal

Price 100.00 INR / Set

Minimum Order Quantity : 1 Set

Shape : Ring / Circular

Lubricating System : Selflubricating or Compatible with Hydraulic Fluids

Power Source : Hydraulic

Noise Level : Silent Operation

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS