Control Valve Seal Kit

Price 100.00 INR/ Set

Control Valve Seal Kit Specification

- Hardness

- 70-90 Shore A

- Finish

- Smooth

- Temperature

- -20C to 220C

- Pressure

- Up to 150 bar

- Load Capacity

- Up to 1000 kg

- Oil Resistance

- Excellent

- Wear Resistance

- High

- Stock

- Available

- Material

- NBR, Viton, PTFE, EPDM

- Style

- Round, O-ring

- Processing Type

- Injection Moulded

- Diameter

- 10 mm to 150 mm

- Thickness

- 2 mm to 15 mm

- Density

- 1.9 Gram per cubic centimeter(g/cm3)

- Application

- Control Valve Sealing

- Compatibility

- Suitable for various valve models

- Tensile Strength

- 12 MPa minimum

- Packaging Type

- Box / Carton

- Colour

- Black, Brown, Green

- Life Expectancy

- Up to 5 years

- Shape

- O-Ring, Gasket

- Elongation at Break

- 250% - 450%

- Resistance to Chemicals

- Strong

Control Valve Seal Kit Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 100 Sets Per Day

- Delivery Time

- 7 Days

About Control Valve Seal Kit

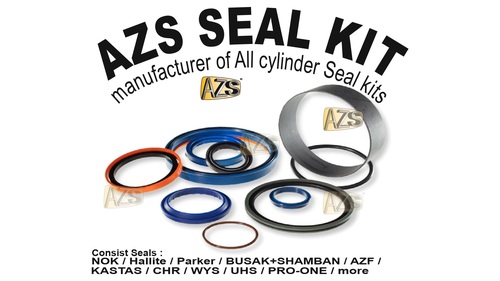

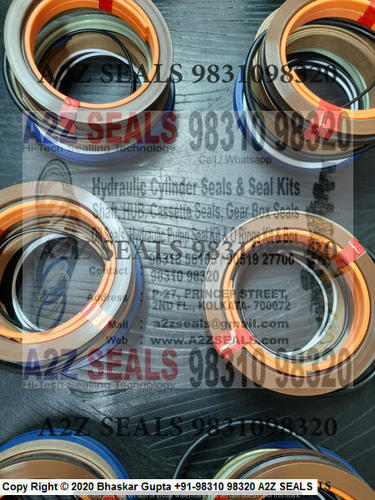

We are identified as one of the leading organizations, engaged in manufacturing and supplying Control Valve Seal Kit. This seal is designed to perform well in extreme corrosive chemical applications including concentrated acids, strong oxidising agents & chemically active organic compounds. We use best quality materials, procured from trusted vendors to manufacture this seal. It is also provided with springs along with its cover if required for acidic fumes application. Control Valve Seal Kit is excellent to prevent the entry of external impurities, so as to achieve excellent sealing performance. It is the most commonly used seal in medium and high pressure hydraulic valves.

Product Details

| Material | Nylon Rubber,Plastic,Polyurethane |

| Size | AS PER OEM''s SPECIFICATIONS |

| Model No. | all models |

| Brand | azs |

| Shape | AS PER OEM & SPECIFICATIONS |

| Style | AS PER OEM & SPECIFICATIONS |

| Packing Type | STD |

Engineered for Versatility and Performance

The Control Valve Seal Kit adapts to a broad range of valve models, offering flexibility in industrial environments. With options in size, thickness, and style, the kits round and O-ring profiles ensure a reliable fit. The resilient materials used enable strong resistance to chemicals, oils, and wear, extending service life and reducing maintenance downtime.

Available in Multiple Colours and Materials

Choose from black, brown, or green seals, manufactured from NBR, Viton, PTFE, or EPDM to suit specific requirements. Each kit undergoes an injection moulding process, ensuring consistent quality and smooth finishes. The seals hardness range of 7090 Shore A and their compatibility with diameters from 10 mm to 150 mm offer solutions for a wide array of operational contexts.

FAQs of Control Valve Seal Kit:

Q: How do I select the appropriate seal kit for my control valve model?

A: You should match the diameter, thickness, and material (NBR, Viton, PTFE, EPDM) of the seals to your valves specifications. Colour options do not affect performance and can help identify applications. Please consult with the supplier or manufacturer to ensure compatibility with your specific valve model.Q: What are the benefits of using this control valve seal kit in chemical-rich environments?

A: This seal kit offers robust resistance to chemicals and oils due to its premium material options and exceptional build quality. Its strong tensile strength and high elongation at break ensure durable sealing even when exposed to aggressive substances, significantly improving system reliability and reducing leaks.Q: Where can these seal kits be purchased within India?

A: Seal kits are available through authorised distributors, importers, exporters, manufacturers, suppliers, and traders across India. Most major industrial supply networks stock them, and they can be ordered directly in box or carton packaging as per your requirement.Q: What is the process for installing these seals in a control valve?

A: Installation involves opening the valve housing, removing old seals, and carefully replacing them with the new O-ring or gasket from the kit. Ensure surfaces are clean and lubricate if recommended. Proper fitting guarantees effective sealing and prolongs the seals service life. Refer to manufacturer guidelines for best results.Q: When should the seal kit be replaced during regular maintenance?

A: Its advisable to replace the seal kit every 35 years, depending on the operating environment and frequency of use. Signs like leaks, hardness loss, or visible wear indicate the need for replacement. Regular inspection will help maintain optimal performance and prevent unplanned downtime.Q: What usage limitations should I be aware of regarding temperature and pressure?

A: The seal kit is designed to operate between -20C and 220C and can withstand pressures up to 150 bar. Operating beyond these parameters may affect seal integrity and shorten its lifespan, so always adhere to recommended temperature and pressure limits.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hydraulic Seal Kit Category

CASE SEAL KIT

Price 100.00 INR / Set

Minimum Order Quantity : 1 Set

Processing Type : Molded

Temperature : 35C to +120C

Application : Hydraulic Cylinders, Construction Machinery

Pressure : Up to 400 Bar

Dresser Seal Kit Oil Seals

Price 100.00 INR / Set

Minimum Order Quantity : 1 Set

Processing Type : Molded

Temperature : 40C to +200C

Application : Hydraulic & Pneumatic Equipment, Oil & Gas Industry

Pressure : Up to 50 MPa

Eimco Elicon Seal Kit Oil Seals

Price 100.00 INR / Set

Minimum Order Quantity : 1 Set

Processing Type : Molded

Temperature : 30C to +110C

Application : Eimco Elicon equipment

Pressure : Up to 10 MPa

Borewell Oil Seal Kit

Price 100.00 INR / Set

Minimum Order Quantity : 1 Set

Processing Type : Molded

Temperature : 40C to +120C

Application : Borewell Pump Sealing

Pressure : Up to 25 MPa

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS