Eaton Pump Seals

Price 100 INR/ Piece

Eaton Pump Seals Specification

- Stock

- Available

- Finish

- Smooth

- Oil Resistance

- Excellent

- Temperature

- -20C to +200C

- Wear Resistance

- High

- Pressure

- Up to 16 bar

- Load Capacity

- Up to 1000 kg

- Hardness

- 70 to 90 Shore A

- Material

- Nitrile Rubber (NBR), Fluorocarbon (Viton), Polyurethane

- Style

- Hydraulic Pump Seal

- Processing Type

- Moulded

- Diameter

- 10 mm to 120 mm

- Thickness

- 3 mm to 15 mm

- Density

- 1.2 Gram per cubic centimeter(g/cm3)

- Application

- Eaton Hydraulic Pumps

- Water Resistance

- Yes

- Standard

- ISO 6194-1

- Elongation at Break

- 300% minimum

- Tensile Strength

- 13 MPa minimum

- Customization

- Available upon request

- Durometer Scale

- Shore A

- Service Life

- Long Life / Extended Service

- Installation

- Press Fit

- Shape

- Round

- Color

- Black or Brown

- Corrosion Resistance

- Yes

Eaton Pump Seals Trade Information

- Minimum Order Quantity

- 1 Set

- FOB Port

- KOLKATA

- Supply Ability

- 100 Sets Per Day

- Delivery Time

- 2 Minutes

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- std

- Main Domestic Market

- Chandigarh, Himachal Pradesh, Sikkim, Manipur, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, , South India, East India, Andaman and Nicobar Islands, Assam, Arunachal Pradesh, Bihar, Delhi, Gujarat, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Lakshadweep, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Nagaland, Odisha, Punjab, Pondicherry, Rajasthan, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, West Bengal, North India, Andhra Pradesh, Central India, West India, Chhattisgarh, All India

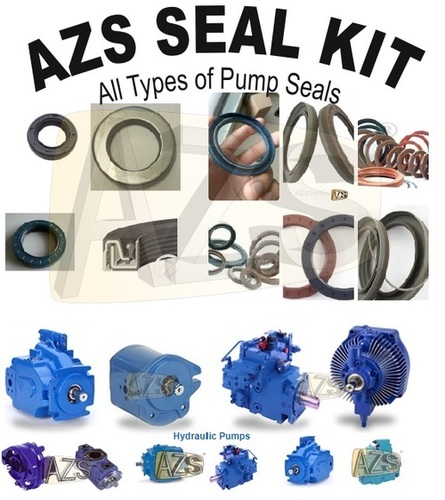

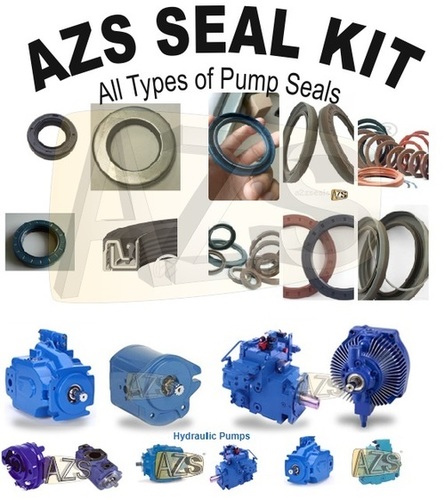

About Eaton Pump Seals

We are the foremost Importer, Assembler, manufacturer and supplier of quality approved range of Hydraulic Pump Seal Kits that are used for preventing from leakage. These kits are designed by connecting with two or more shaft together and control the pressure of air, gas and liquid. Offered kits are manufactured under the observation of our diligent professionals in compliance with set industry norms by making use of quality approved raw material and advanced technology. We provide these Hydraulic Pump Seal Kits in different specifications as per the requirement of our patrons.

We are commercializing in a comprehensive collection of well-designed Hydraulic Pump Motor Seal Kits. They are made under the supervision of world famous brand experts to ensure their life long performing capability without any type of damage or malfunctioning. The kits are extremely demanded by all the users in the market due to excellent and efficient functioning. They have a rugged structured and help in an effective working of hydraulic pumps. The Hydraulic Pump Motor Seal Kits are tested to assure their supreme quality

Special Key Features:

- Precisely engineered

- Corrosion resistance

- High strength

- Dimensional accuracy

Designed for Demanding Hydraulic Applications

Eaton Pump Seals are meticulously moulded to deliver outstanding durability and performance in Eaton hydraulic pumps. Crafted from robust NBR, Viton, or Polyurethane materials, these round seals maintain integrity even under high load, temperature, and pressure conditions. Their superior physical properties and long-lasting service life provide peace of mind for hydraulic system operators.

Precision Manufacturing & Versatile Sizing

Available in diameters ranging from 10 mm to 120 mm and thicknesses from 3 mm to 15 mm, these seals are precision-moulded to meet a variety of application requirements. The smooth finish, high density, and consistent hardness guarantee reliable press-fit installation and ongoing performance.

Comprehensive Resistance & Customization

Eaton Pump Seals exhibit excellent resistance to oil, water, wear, and corrosion, ensuring smooth operation in harsh environments. The seals comply with ISO 6194-1 standards, and customization is available to meet specific operational needs, ensuring optimal compatibility and performance across applications.

FAQs of Eaton Pump Seals:

Q: How are Eaton Pump Seals installed in hydraulic pumps?

A: Eaton Pump Seals are designed for straightforward press-fit installation, ensuring a secure and dependable seal within the pump housing. Their precise dimensions and smooth finish facilitate easy fitting without the need for specialized tools.Q: What materials are available for Eaton Pump Seals, and how do they enhance performance?

A: These seals are available in Nitrile Rubber (NBR), Fluorocarbon (Viton), and Polyurethane. Each material offers unique benefits: NBR provides excellent oil and wear resistance, Viton withstands higher temperatures and chemicals, and Polyurethane delivers outstanding mechanical strength, maximizing lifespan and operational reliability.Q: Can Eaton Pump Seals be customized for specific applications?

A: Yes, customization is available upon request for dimensions, material types, and performance specifications to suit diverse hydraulic pump needs. This ensures a precise fit and compatibility in both conventional and specialized systems.Q: Where can I find Eaton Pump Seals in India?

A: Eaton Pump Seals are readily available throughout India via multiple channels including distributors, exporters, importers, manufacturers, suppliers, and traders, ensuring easy access and prompt delivery nationwide.Q: What benefits do Eaton Pump Seals offer in long-term operations?

A: Engineered with high wear, water, and corrosion resistance and tested for prolonged service under extreme conditions, these seals offer extended lifespan, minimizing maintenance downtime and reducing operational costs over time.Q: What pressure and temperature conditions can Eaton Pump Seals withstand?

A: These seals are capable of operating at pressures up to 16 bar and temperatures ranging from -20C to +200C, making them suitable for demanding hydraulic environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pump Oil Seals Category

Pump Oil Seals

Material : Other, NBR, FKM, PTFE, Silicone

Wear Resistance : High

Temperature : 20C to 120C

Application : Industrial Pumps, Hydraulic Systems

Oil Resistance : Excellent

Finish : Smooth

viton oil seal

Material : Other, Viton (FKM Rubber)

Wear Resistance : Excellent

Temperature : 25C to +200C

Application : Automotive, Industrial Machinery

Oil Resistance : Superior

Finish : Smooth

Concrete Pump Seal

Material : Other, Nitrile Rubber (NBR), Polyurethane, PU Blend

Wear Resistance : High

Temperature : 30C to +120C

Application : Concrete Pump Cylinder, Plunger, Ram & Hydraulic Pistons

Oil Resistance : Excellent

Finish : Smooth

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS