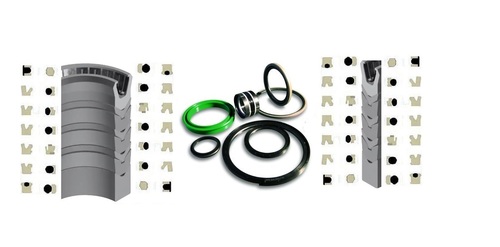

Industrial Seals

Price 100.00 INR/ Set

Industrial Seals Specification

- Capacity

- Designed for Heavy-Duty & Light-Duty Applications

- Noise Level

- Silent Operation

- Size

- Standard & Custom sizes available

- Features

- High Durability, Excellent Chemical & Heat Resistance, Precision Fit

- Usage & Applications

- Industrial Machinery, Automobiles, Hydraulic, Pneumatic, Pumps

- Shape

- Ring / Gasket / Custom

- Diameter

- Available from 10 mm to 1000 mm (or as required)

- Lubricating System

- Optional / As per Application

- Surface Finish

- Smooth / Precision Finished

- Product Type

- Industrial Seals

- Material

- Rubber / Metal / PTFE / Composite

- Technology

- Mechanical Sealing

- Power Source

- Manual / Mechanical

- Pressure

- Up to 10 MPa (Varies by Seal Type)

- Surface Treatment

- Polished / Coated / As per Requirement

- Dimension (L*W*H)

- Customizable / As per Specification

- Weight

- Varies with Size and Material

- Color

- Black / Grey / Brown / Custom

- OEM Service

- Yes

- Installation

- Easy to Install & Replace

- Hardness

- 60-90 Shore A

- Media Compatibility

- Oil, Grease, Water, Chemicals, Air

- Customizability

- Available on request

- Working Life

- Long Service Life

- Temperature Range

- -40°C to +250°C

- Resistant to

- Abrasives, Oils, Fuels, Solvents

- Elasticity

- High Elastic Recovery

Industrial Seals Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 100 Sets, , Per Day

- Delivery Time

- 7 Days

- Main Domestic Market

- Dadra and Nagar Haveli, Chandigarh, Manipur, Andaman and Nicobar Islands, Daman and Diu, Lakshadweep, , South India, East India, West India, Assam, Arunachal Pradesh, Bihar, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Nagaland, Odisha, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttarakhand, West Bengal, Delhi, Gujarat, North India, Punjab, Andhra Pradesh, Central India, Uttar Pradesh, Chhattisgarh, Himachal Pradesh, All India

About Industrial Seals

Surface Excellence & Competitive Edge in Versatile Applications

Industrial Seals offer precision fit and smooth, polished finishes, ensuring reliability across diverse surfacesmetal, rubber, PTFE, and composites. Their high-quality construction delivers a distinct competitive advantage by combining excellent chemical and heat resistance with silent operation. Widely used in hydraulic and pneumatic systems, pumps, and various industrial machinery, these seals maintain peak integrity in environments where reliability is non-negotiable. Industrial Seals provide robust solutions tailored for both demanding heavy-duty and light-duty areas of application.

Market Value, Supply Strength & Shipping Efficiency

Boasting significant market value throughout India, our supply system ensures prompt and consistent delivery of Industrial Seals to meet all domestic demands. Goods are shipped efficiently from trusted FOB ports, guaranteeing on-time arrival within your required schedule. Our robust network of manufacturing, distribution, and export capabilities means customers always have access to readily available inventory. Partner with us to secure commanding supply solutions that optimize every project with matchless reliability and value.

FAQs of Industrial Seals:

Q: How do I choose the right Industrial Seal for my application?

A: To select the ideal seal, consider the specific media, temperature, pressure, and dimension requirements for your application. Our team can guide you in choosing a seal with suitable material, hardness, and design based on your machinery and operating environment.Q: What are the main benefits of using your Industrial Seals in machinery?

A: Our seals provide high durability, exceptional chemical and heat resistance, a precision fit, and silent operation, ensuring long service life and reduced maintenance costs for industrial machinery, automobiles, and fluid handling systems.Q: When is it necessary to customize the size or material of Industrial Seals?

A: Customizing becomes essential when standard sizes or materials do not meet your applications specific pressure, temperature, or media compatibility requirements. We offer custom solutions to ensure optimal performance and reliability.Q: Where are these Industrial Seals most commonly used?

A: These seals are widely utilized in industrial machinery, hydraulic and pneumatic systems, automotive engines, pumps, and environments demanding high resistance to chemicals and extreme temperatures.Q: What is the process for replacing or installing your Industrial Seals?

A: Our seals are designed for easy installation and replacement, generally requiring only basic tools. Detailed instructions or technical support are available to ensure proper fitting and reliable operation in your equipment.Q: How does your supply and shipping process benefit large-scale projects?

A: We maintain robust supply chains and partner with major FOB ports, ensuring consistent market supply and prompt shipping, helping industrial clients meet project schedules without delays.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Spare Parts Category

Pelton Seals

Price 100.00 INR / Set

Minimum Order Quantity : 1 Set

Shape : Round

Product Type : Other, Pelton Seal

Material : Rubber, PTFE (Teflon), or Composite

Diameter : As per specification (customized)

Trenching Machine Seal

Price 100.00 INR / Set

Minimum Order Quantity : 1 Set

Shape : Round/Oval (Specification Based)

Product Type : Other, Trenching Machine Seal

Material : High Grade Rubber & Metal

Diameter : Available from 50 mm to 400 mm

4637675 Seal Group

Price 100.00 INR / Set

Minimum Order Quantity : 1 Set

Shape : Ring

Product Type : Other, Seal Group

Material : Highgrade Rubber, Metal

Diameter : As per OEM specification

Cylinder Seal

Price 100.00 INR / Set

Minimum Order Quantity : 1 Set

Shape : Round

Product Type : Other, Cylinder Seal

Material : Highgrade Rubber

Diameter : 6 mm to 300 mm

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS