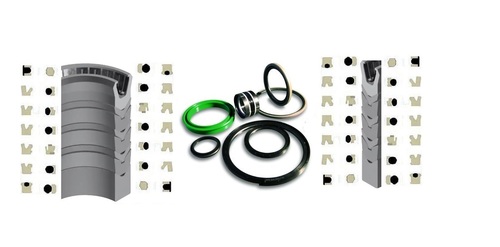

Cylinder Seal

Price 100.00 INR/ Set

Cylinder Seal Specification

- Noise Level

- Silent Operation

- Diameter

- 6 mm to 300 mm

- Usage & Applications

- Hydraulic and pneumatic cylinders, industrial machinery

- Lubricating System

- Oil/Grease compatible

- Shape

- Round

- Capacity

- Depends on application

- Features

- High wear resistance, temperature stability, precise sealing

- Surface Finish

- Smooth

- Size

- Standard & custom sizes

- Product Type

- Cylinder Seal

- Material

- High-grade Rubber

- Technology

- Precision Molding

- Power Source

- Hydraulic / Pneumatic System

- Pressure

- Up to 250 bar

- Surface Treatment

- Polished

- Dimension (L*W*H)

- Custom sizes available

- Weight

- Depends on size

- Color

- Black / Custom

- OEM Compatibility

- Available

- Hardness

- 70-90 Shore A

- Installation

- Easy fit design

- Compression Set

- Low

- Serviceability

- Replaceable

- Temperature Range

- -40°C to 200°C

- Fluid Compatibility

- Hydraulic oils, water, air

- Chemical Resistance

- Excellent

- Packaging

- Corrugated box / bulk

- Elastomer Type

- Nitrile Rubber, Polyurethane, Viton

- Environmental Compliance

- RoHS compliant

- Longevity

- Extended service life

Cylinder Seal Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 100 Sets, , Per Day

- Delivery Time

- 7 Days

- Main Domestic Market

- Manipur, Himachal Pradesh, Andaman and Nicobar Islands, Nagaland, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Lakshadweep, , South India, East India, West India, Andhra Pradesh, Assam, Arunachal Pradesh, Chandigarh, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Delhi, Gujarat, North India, Bihar, Central India, Uttar Pradesh, Odisha, Chhattisgarh, All India

About Cylinder Seal

Assisted by a hardworking team of professionals, our firm is affianced in presenting supreme qualityHydraulic Cylinder Seal.The seal provided by us is extensively used for fixing leakage problems in hydraulic engines. Offered seal is manufactured by utilizing premium grade raw material with the help of modern manufacturing trechniques. ThisHydraulic Cylinder Sealismade available in various sizes as per the exact needs of the customers. Clients can get this seal from us at industry leading rates

Features

-

High strength

-

Heat resistance

-

Fine finish

-

Durability

Engineered for Performance and Durability

Our Cylinder Seals are meticulously designed to deliver consistent, reliable sealing in both hydraulic and pneumatic cylinders. Built with advanced elastomers like Nitrile, Polyurethane, and Viton, they resist wear, extreme temperatures, and harsh fluids. Precision molding and polished surface treatments ensure a smooth finish, enhancing the longevity and sealing efficiency. Whether used in industrial machinery or lubricating systems, these seals offer stable operation and minimal maintenance.

Custom Solutions and Easy Integration

Available in both standard and custom dimensions, our seals provide flexible options for different cylinder types and operational requirements. The easy fit design significantly simplifies installation and replacement, reducing downtime and supporting high serviceability. With OEM compatibility, customers can confidently integrate these seals into new builds or retrofit existing equipment for improved performance.

FAQs of Cylinder Seal:

Q: How do I install the Cylinder Seal in my hydraulic or pneumatic cylinder?

A: The Cylinder Seal features an easy-fit design, allowing for straightforward installation. Simply select the appropriate size (from 6 mm to 300 mm diameter), ensure the sealing surfaces are clean and lubricated, and press the seal into the groove. Detailed installation guidelines are available upon request.Q: What types of materials are used for these Cylinder Seals?

A: Our Cylinder Seals are manufactured using high-grade Nitrile Rubber, Polyurethane, and Viton elastomers. These materials offer excellent chemical resistance, high wear resistance, and stable performance across a wide temperature range (-40C to 200C).Q: When should I replace a Cylinder Seal?

A: Replacement intervals vary depending on operating conditions, but seals should be inspected regularly for signs of wear, deformation, or leakage. Thanks to their extended service life and low compression set, our seals typically require less frequent replacement compared to standard seals.Q: What benefits do these Cylinder Seals offer for industrial applications?

A: With precise sealing, high temperature and chemical resistance, silent operation, and extended service life, these Cylinder Seals minimize downtime and maintenance costs. Their versatility makes them suitable for use in hydraulic and pneumatic cylinders across various industrial applications.Q: Where can I use these seals and what fluids are they compatible with?

A: These seals are ideal for hydraulic and pneumatic cylinders, industrial machinery, and lubricating systems. They are compatible with hydraulic oils, water, air, and other common industrial fluids, supporting diverse applications in manufacturing and processing environments.Q: Is OEM compatibility and environmental compliance addressed with these seals?

A: Yes, our Cylinder Seals are compatible with OEM specifications, accommodating standard as well as custom sizing. They are RoHS compliant, adhering to environmental safety standards, and are available for distribution, export, and supply across India.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Spare Parts Category

Pelton Seals

Price 100.00 INR / Set

Minimum Order Quantity : 1 Set

Power Source : Other, Mechanical

Size : Standard & Customized

Weight : Varies as per model

Dimension (L*W*H) : As per model (customized)

Francis Seals

Price 100.00 INR / Set

Minimum Order Quantity : 1 Set

Power Source : Hydraulic

Size : Varies (Customized Available)

Weight : Multiple Weights as per Size

Dimension (L*W*H) : Standard & Custom Sizes

Rubber Kaplan Seals

Price 100.00 INR / Set

Minimum Order Quantity : 1 Set

Power Source : Other, Manual

Size : As per requirement

Weight : Varies with size

Dimension (L*W*H) : Customized as per application

Chevron Packing Seal

Price 100.00 INR / Set

Minimum Order Quantity : 1 , , Set

Power Source : Other, Manual

Size : From 10 mm up to 400 mm

Weight : Depends on dimensions

Dimension (L*W*H) : Custom sizes available

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS