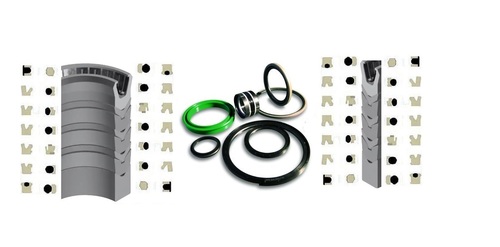

Rubber Kaplan Seals

Price 100.00 INR/ Set

Rubber Kaplan Seals Specification

- Lubricating System

- Required as per application

- Features

- Waterproof, Abrasion Resistant, Durable, Heat Resistant

- Surface Finish

- Polished

- Noise Level

- Silent Operation

- Shape

- O-Ring / Circular / Custom Shape

- Diameter

- As per turbine specification

- Size

- As per requirement

- Usage & Applications

- Kaplan Turbine Sealing, Hydro Power Plants

- Capacity

- Customizable

- Product Type

- Rubber Kaplan Seal

- Material

- High-Grade Rubber

- Technology

- Compression Molding

- Power Source

- Manual

- Pressure

- High Pressure Tolerant

- Surface Treatment

- Smooth Finish

- Dimension (L*W*H)

- Customized as per application

- Weight

- Varies with size

- Color

- Black

- Temperature Range

- -40°C to +120°C

- Storage Recommendations

- Store in cool, dry place away from direct sunlight

- Chemical Resistance

- Excellent against oil, water, and grease

- Elongation at Break

- 400% Approx.

- Standards Met

- Meets Hydro Turbine Industry Standards

- Installation

- Easy to Fit and Replace

- Hardness

- 60-80 Shore A

- Service Life

- Long-lasting

- Tensile Strength

- Strong and Durable

Rubber Kaplan Seals Trade Information

- Minimum Order Quantity

- 1 Set

- FOB Port

- KOLKATA

- Supply Ability

- 100 Sets Per Day

- Delivery Time

- Minutes

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- STD

- Main Domestic Market

- Himachal Pradesh, Andaman and Nicobar Islands, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Lakshadweep, West Bengal, Assam, Uttar Pradesh, Jammu and Kashmir, Arunachal Pradesh, Madhya Pradesh, , East India, Goa, Sikkim, Tamil Nadu, Haryana, South India, Jharkhand, Meghalaya, Maharashtra, Karnataka, Chandigarh, Rajasthan, Andhra Pradesh, Pondicherry, Delhi, Telangana, Gujarat, Mizoram, Manipur, Tripura, Nagaland, North India, Punjab, Bihar, Kerala, Central India, Odisha, West India, Chhattisgarh, All India

About Rubber Kaplan Seals

Seal Kits including

Cylinder Seals & Seal Kits - Hydraulic Seal Kits, Hydraulic Seals, Piston Seals, Rod seals, Wiper Seals, Wear Rings, Dust Seals, O Rings & Back Up Rings

Oil Seals - Shaft Seals | HUB Seals | Cassette Seals | Gear Box Seals | Pump Oil Seals of Brands like NOK, NDK, CR, NATIONAL, NAK, TCK, SOG of Germany, Japan, etc

O Rings - O Ring Box | O Ring Kits

Floating Seals - GNL, Italy & Deril Seals

Design and supplies complete range of product of different size, profile, type, quality products of U.S. GERMANY, JAPAN, etc produce by Brands i.e. BULLDOG, NOK, SIMRIT, CFW, PARKER, KASTAS, BUSAK + SHAMBAN, HALLITE, AZF and more some of which are being used by OEMs in their machines, hydraulic cylinders, other applications. We have decades of experience in delivering top-notch solutions to industries including

We customise the Kits as per the requirement of the customers along with AZS Replacement seal kits for all OEMs. We provide Seal Kits for various excavators, back-hoe loaders, dumpers, dozers, wheel loaders, forklifts, cranes etc.. We keep ready range of seals for various part numbers with OEM references.

Exceptional Durability and Performance

Designed with advanced compression molding technology, Rubber Kaplan Seals withstand harsh operational conditions, offering a strong tensile profile and impressive elongation at break. Their robust chemical resistance and high-pressure tolerance ensure reliable sealing in hydro power plants and lubricating systems. The smooth, polished finish reduces friction, supports silent operation, and extends the products service life.

Flexible Applications and Easy Installation

Available in O-ring, circular, or custom shapes, these seals can be tailored to specific turbine requirements. Installation is straightforward, enabling quick replacement during maintenance intervals. Suitable for various hydro turbine models, their waterproof and abrasion-resistant features maximize operational safety and efficiency.

Compliance and Longevity

Manufactured to meet hydro turbine industry standards, Rubber Kaplan Seals assure high-quality performance and lasting functionality. Their excellent resistance to oil, water, and grease, combined with recommended proper storage conditions, helps retain softness and elasticity over extended periods, reducing downtime and maintenance costs.

FAQs of Rubber Kaplan Seals:

Q: How are Rubber Kaplan Seals installed in hydro turbines?

A: Rubber Kaplan Seals are designed for easy fitting and replacement. Their flexible material and custom dimensions allow straightforward installation into turbine sealing grooves without specialized tools. Proper lubrication may be required during the process for optimal performance.Q: What makes these seals suitable for high-pressure hydro power applications?

A: With a tensile strength rated as strong and durable, hardness of 60-80 Shore A, and tolerance for high operating pressures, these seals reliably maintain a leak-proof barrier even under challenging conditions typical in hydro power plants.Q: When should Rubber Kaplan Seals be replaced?

A: Replacement intervals depend on operational wear and regular maintenance schedules. Signs to replace include visible damage, excessive wear, or reduced sealing performance, ensuring continued reliability and safety of the turbine system.Q: Where should these seals be stored to maintain their quality?

A: Store Rubber Kaplan Seals in a cool, dry place away from direct sunlight and sources of ozone. Following these recommendations preserves the material properties and extends the seals service life before installation.Q: What benefits do Rubber Kaplan Seals offer for hydro turbine systems?

A: These seals deliver waterproof, heat and abrasion-resistant protection with silent operation. Their long-lasting service life reduces downtime and minimizes maintenance costs, while excellent chemical resistance ensures optimal performance in turbines exposed to oil, water, or grease.Q: What is the process used in manufacturing Rubber Kaplan Seals?

A: Rubber Kaplan Seals are produced using precision compression molding technology, which ensures uniform density and a smooth, polished finish. This process provides robust mechanical properties tailored to hydro turbine specification requirements.Q: Can the seals be customized for various turbine models and requirements?

A: Yes, the seals are available in a range of shapes, diameters, and sizes, offering full customization to match specific Kaplan turbine configurations and applications as indicated during order placement.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Spare Parts Category

Pelton Seals

Price 100.00 INR / Set

Minimum Order Quantity : 1 Set

Surface Finish : Smooth Finish

Features : Corrosion Resistant, High Durability, Excellent Sealing, Easy Installation

Lubricating System : SelfLubricated or External (as per model)

Dimension (L*W*H) : As per model (customized)

Francis Seals

Price 100.00 INR / Set

Minimum Order Quantity : 1 Set

Surface Finish : Fine Finish

Features : Leakproof, Wearresistant, Long service life

Lubricating System : Self Lubricating

Dimension (L*W*H) : Standard & Custom Sizes

Chevron Packing Seal

Price 100.00 INR / Set

Minimum Order Quantity : 1 , , Set

Surface Finish : Smooth/Semifinished

Features : Leakproof, wearresistant, high durability

Lubricating System : Requires external lubrication

Dimension (L*W*H) : Custom sizes available

Gas Seals

Price 100.00 INR / Set

Minimum Order Quantity : 1 Set

Surface Finish : Smooth

Features : LeakProof, Corrosion Resistant, Low Maintenance

Lubricating System : Dry Running / Gas Lubricated

Dimension (L*W*H) : Custom Sizes Available

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS